Signs Your Netzsch Pump Parts Need Replacement

Netzsch pumps are renowned for their reliability and efficiency in various industrial applications. However, like any mechanical system, the components of a Netzsch pump may eventually wear out or become damaged. Recognizing the signs that your Netzsch pump parts need replacement is crucial to maintaining optimal performance and preventing costly downtime. This article will explore some common indicators that suggest it’s time to replace your pump parts.

Common Signs of Wear and Tear

1. Unusual Noises

One of the first indicators that something is wrong with your Netzsch pump is the emergence of unusual noises. If you start hearing grinding, rattling, or excessive vibration, it may point to worn bearings, damaged rotors, or misalignment. Addressing these noises promptly can prevent more severe damage and costly repairs.

2. Decreased Efficiency

Another sign that your Netzsch pump parts may need replacement is a noticeable drop in efficiency. If you observe that the pump is struggling to maintain its flow rate or pressure, it could be due to wear on internal components such as the stator or rotor. Inadequate performance not only affects productivity but can also lead to increased energy consumption.

3. Leakage

Leaks are a clear indication that something is amiss with your pump. If you notice fluid seeping from the pump housing or connections, it might mean that seals or gaskets are deteriorating. Prompt replacement of these parts is essential to prevent further damage and ensure safe operation.

4. Increased Maintenance Frequency

If you find yourself performing maintenance on your Netzsch pump more frequently than usual, it’s a sign that parts may be wearing out. Increased wear typically leads to more frequent repairs and inspections. If maintenance becomes a regular necessity, it’s advisable to evaluate the condition of the pump parts and consider replacements.

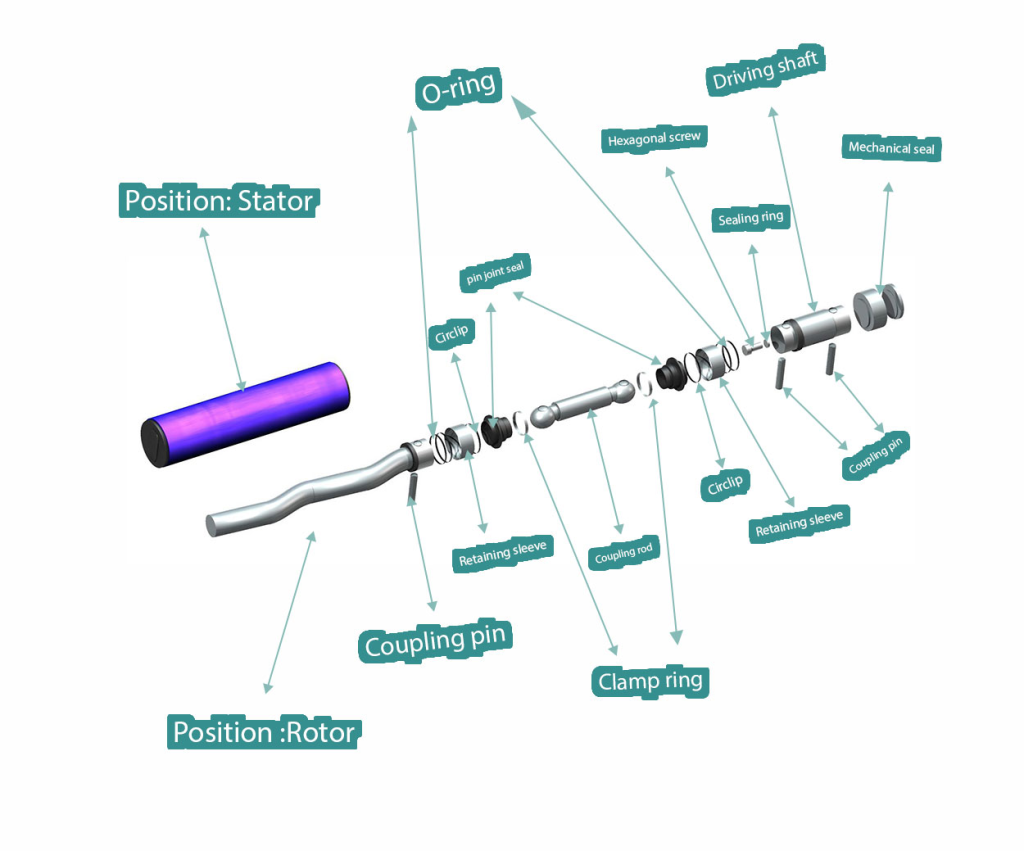

Visual Inspection

Conducting a visual inspection of your Netzsch pump can provide valuable insights into its condition. Look for:

- Cracks or Damage: Inspect the housing and internal components for any visible cracks or signs of damage.

- Corrosion: Check for rust or corrosion, which can weaken the structural integrity of parts.

- Worn Surfaces: Examine the surfaces of rotors and stators for wear patterns that could indicate the need for replacement.

Conclusion

Regular monitoring and maintenance of your Netzsch pump are essential for ensuring its longevity and efficiency. By being vigilant and recognizing the signs that your Netzsch pump parts need replacement, you can prevent unexpected breakdowns and costly repairs. If you notice any of the symptoms mentioned above, it may be time to consult with a professional to assess the situation and determine the necessary replacements. Keeping your pump in optimal condition will not only enhance performance but also extend its lifespan, ensuring reliable operation for your industrial needs.