Metal Stamping Supplier Selection Guide: Quality, Materials, and Experience

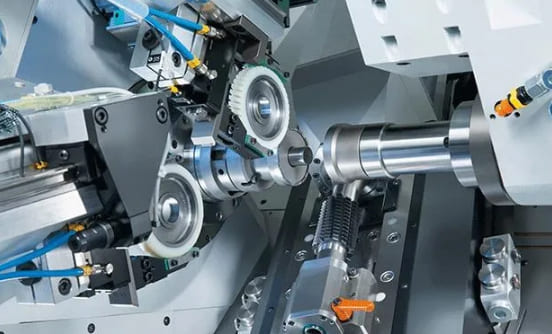

Metal stamping is a crucial process in the manufacturing of geosynthetics, encompassing various metal-forming techniques that shape and transform materials into the desired components. When choosing a metal stamping supplier for geosynthetics, it is essential to consider specific factors that align with the unique requirements of this industry.

Quality

Ensuring high-quality production is paramount when selecting a metal stamping supplier for geosynthetics. Here are some key aspects to evaluate:

Design: A reliable supplier, such as GeoFanTex, should provide design recommendations that help prevent defects and minimize future expenses. By understanding the step-by-step metal stamping process required for geosynthetics, GeoFanTex can design parts that optimize performance and minimize design costs.

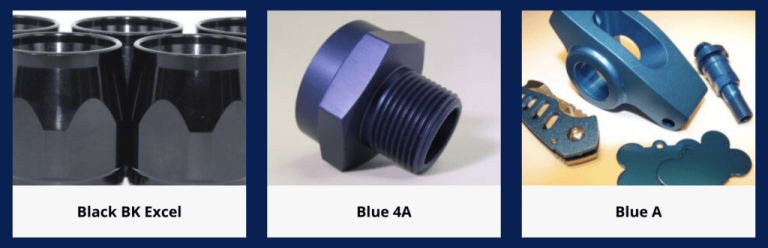

Materials: The best metal stamping suppliers have expertise in working with a wide range of materials suitable for geosynthetics. GeoFanTex’s extensive experience with materials like steel, stainless steel, brass, copper, aluminum, titanium, and more enables them to guide material selection based on each metal’s unique properties, ensuring optimal performance in geosynthetic applications.

Experience: Choosing a supplier with relevant experience in the geosynthetics industry is crucial. GeoFanTex possesses the necessary expertise, precision, and quality standards to manufacture geosynthetic components successfully. With a track record of working in precision-demanding sectors such as automotive, medical, and aerospace, GeoFanTex understands the stringent requirements of geosynthetic applications.

Production Capabilities and Capacity

To meet the demands of the geosynthetics industry, it is important to consider the following aspects of a metal stamping supplier’s production capabilities and capacity:

Vertically Integrated: GeoFanTex offers a comprehensive approach, managing the entire project from design to delivery. By partnering with their design and engineering experts, you can ensure that your geosynthetic components are optimized for performance and manufacturability. GeoFanTex manufactures tools in-house and provides additional services such as assembly, secondary operations, and finishing to streamline the production process.

Flexibility: In an industry prone to supply chain disruptions and material price fluctuations, a flexible metal stamping supplier like GeoFanTex is invaluable. Their long-standing relationships with metal vendors and market insights enable them to recommend alternative designs and materials, ensuring on-time completion of your geosynthetic project at a reasonable cost.

Response Times: Timely project completion is crucial, and a responsive metal stamping supplier plays a significant role in achieving this. GeoFanTex emphasizes effective communication and quick response times, ensuring that your project progresses smoothly and meets production deadlines.

Industry Experience: GeoFanTex’s extensive experience spans multiple industries, including aerospace, automotive, medical, defense, lighting, renewable energy, and mechanical, electrical, and plumbing (MEP). Their team’s vast knowledge and understanding of industry-specific regulations and quality standards make them well-equipped to meet the unique requirements of geosynthetic applications.