Optimizing EV Manufacturing: The Role of Metal Stamping & Geogrid Technology

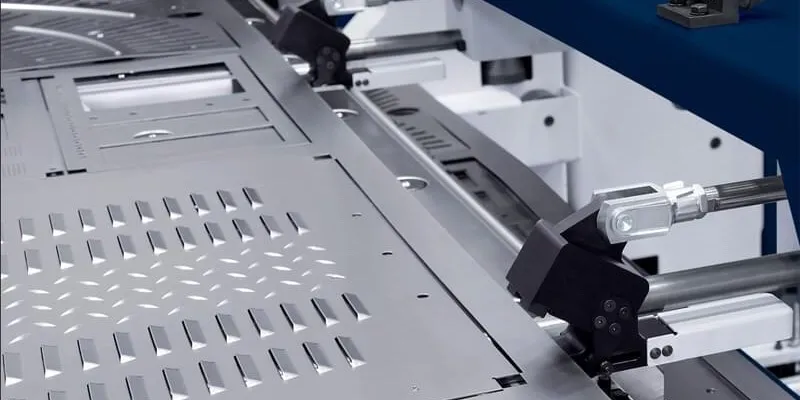

Metal stamping, a highly efficient process employing stamping presses and dies, transforms metal sheets into desired shapes. Renowned for its efficiency, it crafts intricate parts meeting stringent tolerances and specifications with consistent precision. This technique holds pivotal importance in the automotive industry, especially in the manufacturing of electric vehicles (EVs).

The significance of automotive metal stamping in the EV sector lies in its ability to fabricate complex, lightweight components that curtail fuel consumption and carbon emissions. It serves as an optimal solution, ensuring material efficiency and cost-effectiveness in part production. At ESI, comprehending the challenges faced by our automotive clientele, we offer an array of manufacturing services and engineering solutions tailored to meet the industry’s rigorous demands. Incorporating innovative technologies such as Geogrid in our automated systems enables us to deliver safety-critical EV parts promptly, maintaining superior quality and efficiency.

Applications in the EV Stamping Industry

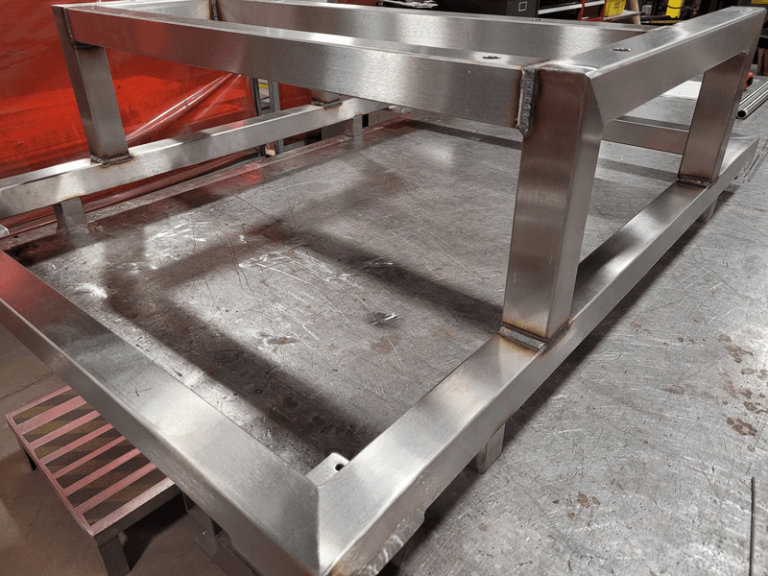

Metal stamping, synergized with advanced technologies like Geogrid, plays a pivotal role in the EV industry, fabricating highly precise components aligning with strict design parameters and compliance regulations. The adaptability and customization potential of EV stamping processes empower manufacturers to create an extensive array of parts across various sizes. Common applications of EV metal stamping encompass:

- A-frames

- Battery trays

- Body in white (BIW) components

- Brackets

- Brake parts

- EV battery parts

- EV charging parts

- Floor panels

- Heat shields

- Seating components

- Transmission systems and components