Exploring the Essentials: Understanding Gear in Mechanical Systems

Gears are fundamental components in mechanical systems, playing a crucial role in transmitting power and motion between rotating shafts. This article delves into the intricacies of gears, their types, applications, and maintenance practices to enhance your understanding of these critical mechanical elements.

What are gears and how do they work?

Gears are toothed mechanical components that mesh with each other to transmit rotational motion and torque. They work by transferring power from one shaft to another, altering the speed, torque, and direction of rotation as per the gear ratio.

What are the different types of gears commonly used?

There are several types of gears, each suited for specific applications:

- Spur Gears: Used in parallel shaft arrangements for speed reduction or increase.

- Helical Gears: Offer smoother and quieter operation compared to spur gears.

- Bevel Gears: Transmit power between intersecting shafts at right angles.

- Worm Gears: Provide high gear reduction ratios and are ideal for applications requiring quiet operation.

Where are gears used in industrial applications?

Gears find extensive use across various industries:

- Automotive: Transmission systems for speed and torque control.

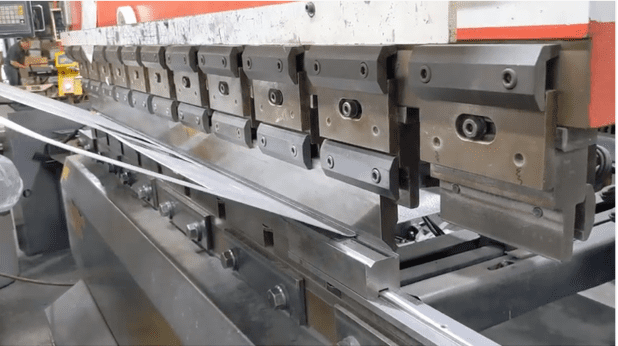

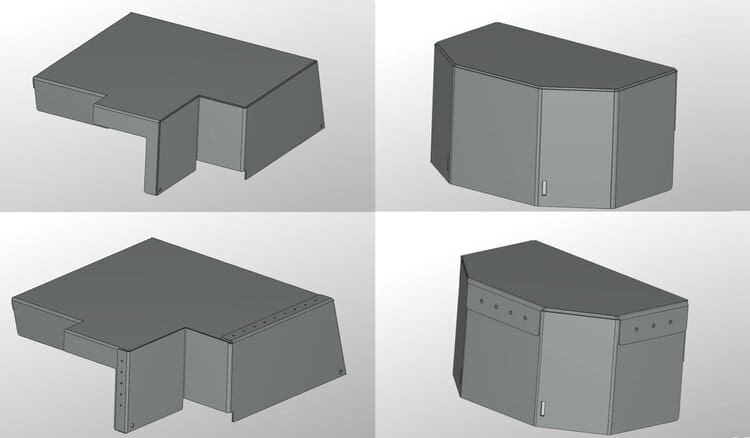

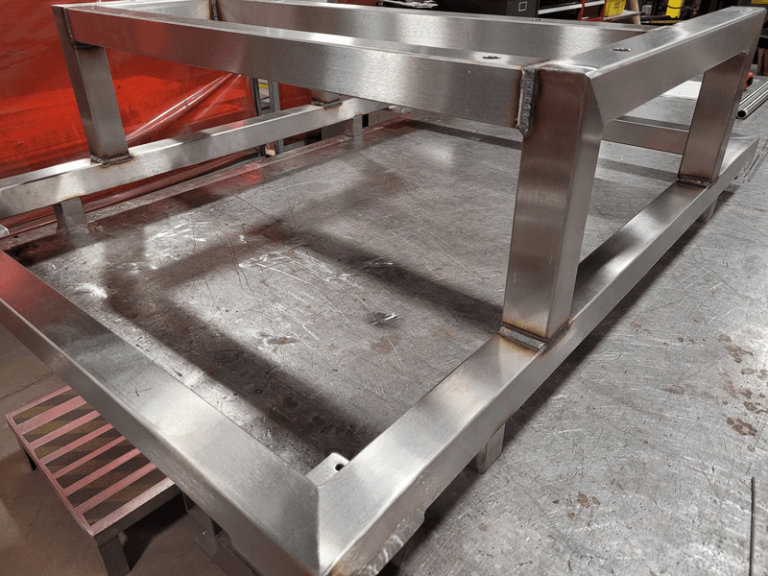

- Manufacturing: Machinery for milling, cutting, and shaping.

- Aerospace: Control systems and landing gear mechanisms.

- Power Generation: Turbines and windmills for power transmission.

How important is maintenance for gears?

Maintenance is crucial to ensure gears operate efficiently and reliably:

- Lubrication: Regularly lubricate gears to reduce friction and wear.

- Inspection: Check for wear patterns, misalignment, and tooth damage.

- Alignment: Ensure proper alignment of shafts and gears to prevent premature failure.

- Temperature Control: Monitor operating temperatures to prevent overheating.

Gears are indispensable in mechanical engineering, facilitating the controlled transmission of power and motion across various applications. Understanding gear types, their functionality, and maintenance requirements ensures optimal performance and longevity in mechanical systems. Whether in automotive, manufacturing, or aerospace, gears play a pivotal role in shaping modern technology and industrial processes.

This article has provided a comprehensive overview of gears, highlighting their types, applications, maintenance practices, and importance in mechanical systems. By implementing proper maintenance routines and understanding gear principles, engineers and technicians can enhance operational efficiency and reliability in their respective fields. This article also touches upon the importance of geomembrane in industrial settings, emphasizing its role in environmental protection and containment solutions.