A Step-by-Step Guide to KMA1265 Case idler Assembly

A Step-by-Step Guide to KMA1265 Case Idler Assembly

The KMA1265 Case idler assembly is crucial for the effective operation of heavy machinery. Proper installation and maintenance ensure optimal performance and extend the lifespan of your equipment. This guide will walk you through the step-by-step process of assembling and installing the KMA1265 idler assembly.

Step 1: Gather Necessary Tools and Materials

Before starting, ensure you have the following tools and materials ready:

- Tools:

- Socket wrench set

- Torque wrench

- Screwdrivers (flat and Phillips)

- Pry bar

- Grease gun

- Cleaning rags

- Materials:

- KMA1265 idler assembly

- Grease

- Replacement seals (if necessary)

- Safety gear (gloves, goggles)

Step 2: Safety First

- Turn Off Equipment: Ensure that the machinery is turned off and the key is removed.

- Secure the Area: Clear the work area of any obstacles and ensure it is safe to work.

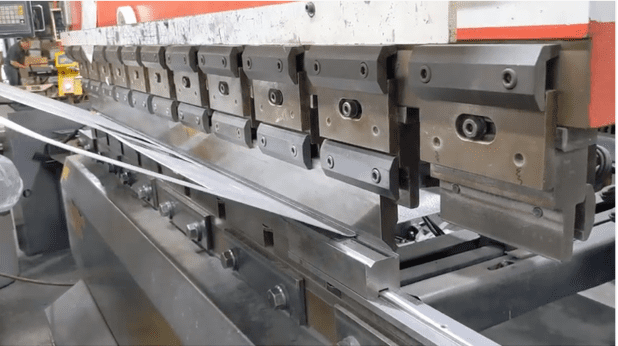

Step 3: Remove the Old Idler Assembly

- Disconnect Power: Make sure the equipment is powered down.

- Support the Machine: Use jack stands to secure the machinery and prevent it from moving.

- Remove Track: Detach the track from the old idler assembly. Use a pry bar if necessary to separate the track from the idler.

- Unbolt Idler Assembly: Remove the bolts securing the old idler assembly to the frame of the machine. Keep these bolts for reuse unless they are damaged.

- Take Out Old Idler: Carefully remove the old idler assembly from its position.

Step 4: Prepare for Installation

- Inspect Mounting Area: Clean the mounting area on the machine frame to remove dirt, debris, and old grease.

- Check New Idler Assembly: Inspect the new KMA1265 idler assembly for any damage and ensure that all necessary components are included.

Step 5: Install the New Idler Assembly

- Position the New Idler: Align the new KMA1265 idler assembly with the mounting holes on the machine frame.

- Insert Bolts: Hand-tighten the bolts into place to secure the idler assembly temporarily.

- Torque Bolts: Use a torque wrench to tighten the bolts to the manufacturer’s specifications, ensuring they are secure.

Step 6: Reattach the Track

- Align Track: Carefully position the track over the new idler assembly.

- Secure Track: Use the appropriate method to reattach the track, ensuring it is seated correctly on the idler.

Step 7: Lubricate the Idler Assembly

- Use a Grease Gun: Inject grease into all grease fittings on the idler assembly to ensure proper lubrication.

- Check for Leaks: After lubrication, inspect for any leaks around seals and fittings.

Step 8: Final Checks

- Inspect Alignment: Make sure the idler assembly and track are correctly aligned.

- Test Movement: Manually rotate the track to ensure it moves freely without obstruction.

- Check Tension: Adjust the track tension as per the manufacturer’s recommendations.

Step 9: Start the Equipment

- Turn On the Machinery: Start the equipment and observe the operation of the new idler assembly.

- Listen for Sounds: Pay attention to any unusual noises during operation which may indicate issues.

Step 10: Document the Installation

- Record Details: Note the date of installation and any observations during the process.

- Schedule Next Maintenance: Set a reminder for the next inspection and lubrication.

Conclusion

Following this step-by-step guide will help you successfully assemble and install the KMA1265 Case idler assembly. Regular maintenance and inspections will ensure the longevity and performance of your machinery. If you have any further questions or need assistance, feel free to reach out!