Cost-Effective Manufacturing: Sheet Metal Stamping vs. Metal Fabrication

When manufacturing metal parts and components, it’s essential to choose the right manufacturing process. Two commonly used processes are sheet metal stamping and metal fabrication. While these terms are sometimes used interchangeably, they encompass different manufacturing techniques that offer unique advantages. In this article, we will explore the differences between sheet metal stamping and metal fabrication, helping you make an informed decision for your manufacturing needs.

Sheet Metal Stamping:

Sheet metal stamping is a cost-effective fabrication process that involves using dies, punches, and other tools to shape sheet metal into the desired end component. This method is particularly suitable for large production runs and can be performed in a single or multiphase process. Multiphase or progressive die stamping involves passing a strip of metal through a series of tooling stations, each performing different punches, cuts, or bends. The cumulative effect of these stations results in a completed product at the end of the run.

Advantages of sheet metal stamping include:

- Lower cost per piece with larger runs

- Capability to accommodate complex designs

- Highly repeatable process

- Availability of secondary processing options

If you require parts in large quantities, sheet metal stamping can be a favorable option. However, it’s important to consider that stamping costs may increase due to tooling expenses and longer preparation periods.

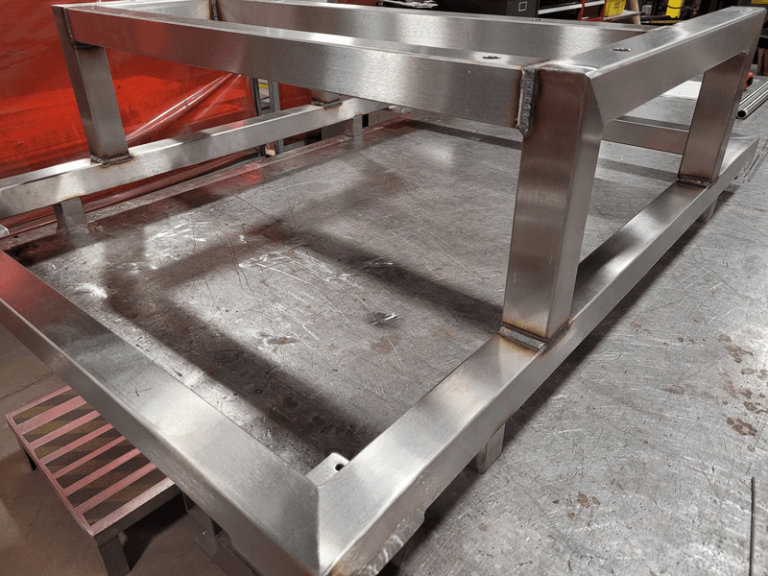

Metal Fabrication:

Metal fabrication is a broader term that encompasses various manufacturing processes such as cutting, bending, and punching. It involves shaping metal parts through the removal or alteration of materials. For example, metal fabrication processes may include creating cutouts or holes in metal materials or changing the shape of metal through stretching and bending.

Advantages of metal fabrication include:

- Rapid prototyping capabilities

- Versatile fabrication techniques like laser cutting and shearing

- Diverse customization options

- Quick and easy design adjustments

While sheet metal fabrication is suitable for many metal manufacturing applications, it typically requires more labor and longer production periods compared to sheet metal stamping. Additionally, the costs of materials used in fabrication tend to be higher, and fabricating complex designs may be challenging.

Furthermore, metal fabrication is less compatible with high-volume production runs due to its lack of repeatability. However, it offers a cost-effective and efficient solution for applications that require low-volume production of pieces with simpler designs.

Choosing the Right Manufacturing Process:

When deciding between sheet metal stamping and metal fabrication, consider the following factors:

- Quantity of parts needed: Sheet metal stamping is ideal for large production runs, while metal fabrication suits low-volume production.

- Complexity of designs: Sheet metal stamping can accommodate complex designs, whereas metal fabrication is better suited for simpler designs.

- Cost considerations: Sheet metal stamping offers a lower cost per piece for larger runs, while metal fabrication can be more cost-effective for low-volume production.

Selecting the appropriate manufacturing process is crucial when producing metal parts and components. By understanding the differences between sheet metal stamping and metal fabrication, you can make an informed decision based on your specific requirements. Whether you opt for sheet metal stamping or metal fabrication, partnering with a reliable manufacturing service provider like Engineering Specialties, Inc. (GeoFanTex) ensures high-quality results. With their extensive experience and automated systems, GeoFanTex delivers dependable manufacturing services tailored to your needs. Contact GeoFanTex today for reliable sheet metal stamping services using state-of-the-art technology and skilled personnel.