The Ultimate Guide to Alloys: Understanding Their Importance and Applications

Alloys are essential materials in modern engineering and manufacturing, combining the properties of different metals to enhance performance and durability. By blending various metals, alloys can achieve characteristics that are superior to those of pure metals, such as increased strength, corrosion resistance, and improved machinability. This article explores the fundamental concepts of alloys, their diverse applications, and how they relate to materials like geonet, which are crucial in construction and environmental engineering.

What is an alloy and how is it made?

An alloy is a mixture of two or more elements, with at least one of them being a metal. The primary purpose of creating alloys is to improve the properties of the base metal. Alloys are typically made by melting the components together, allowing them to blend at a molecular level. Common examples include steel (an alloy of iron and carbon) and bronze (an alloy of copper and tin). The specific properties of an alloy depend on its composition and the method used to create it.

What are the main types of alloys?

There are several types of alloys, including:

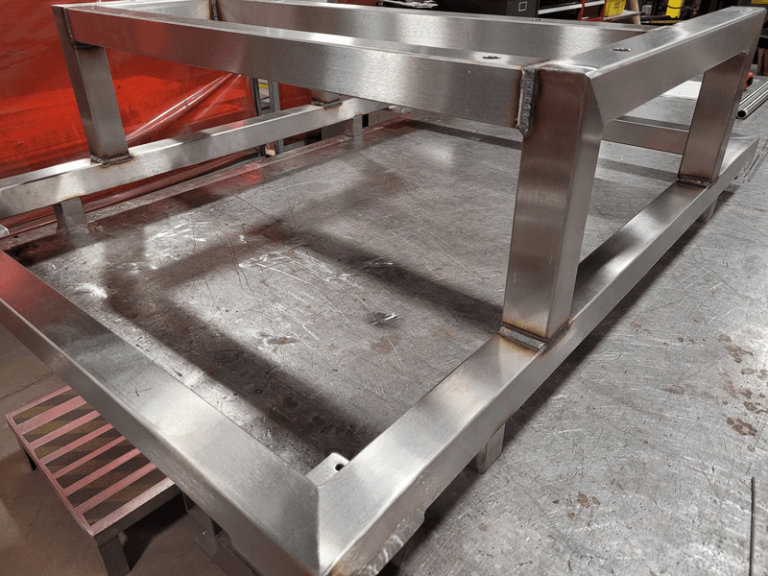

- Ferrous Alloys: These contain iron as the base metal, such as steel and cast iron. They are widely used in construction, automotive, and manufacturing industries due to their strength and durability.

- Non-Ferrous Alloys: These do not contain iron and include materials like aluminum alloys, brass (copper and zinc), and bronze. They are valued for their corrosion resistance, lightweight nature, and electrical conductivity.

- High-Performance Alloys: These are designed for specific applications requiring extreme conditions, such as aerospace and medical industries. Examples include titanium alloys and superalloys.

How do alloys compare to pure metals?

Alloys often outperform pure metals in various aspects. For example:

- Strength and Hardness: Alloys like steel are much stronger and harder than pure iron, making them suitable for structural applications.

- Corrosion Resistance: Non-ferrous alloys such as stainless steel offer excellent resistance to rust and corrosion compared to pure metals.

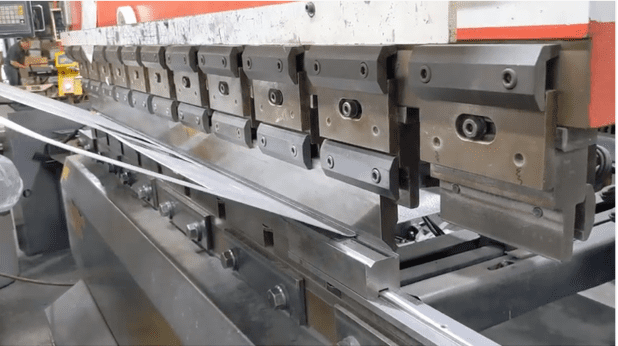

- Cost and Machinability: Some alloys can be more cost-effective and easier to machine than pure metals, optimizing manufacturing processes.

How does geonet relate to alloy materials?

Geonet is a type of geosynthetic material used in civil engineering for soil stabilization and drainage. It consists of a network of interconnected strands, typically made from polymers. Although geonet itself is not an alloy, the performance of geonets can be enhanced by alloy components used in manufacturing the machinery and tools involved in their production. Additionally, the use of alloys in construction equipment ensures the durability and efficiency of geonet installation and maintenance.

Alloys play a crucial role in enhancing the properties of metals for various applications, from everyday items to advanced technologies. By combining different elements, alloys achieve characteristics that surpass those of pure metals, including increased strength, corrosion resistance, and improved machinability. Understanding the different types of alloys and their applications can help industries select the right materials for their needs. While geonet itself is not an alloy, the use of alloy-based tools and equipment in its production and application highlights the broader importance of alloys in modern engineering and construction.