The Role of Lubricants in Enhancing Performance: A Comprehensive Guide

Lubricants play a crucial role in various industries, from automotive to manufacturing and beyond. Understanding their significance and application is essential for optimizing efficiency and prolonging the lifespan of machinery and equipment. In this article, we delve into the world of lubricants, exploring their functions, types, and importance in different sectors.

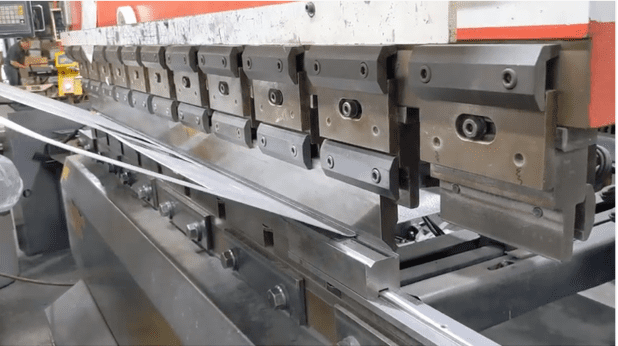

What is the primary function of lubricants?

Lubricants primarily serve to reduce friction and wear between moving parts, thereby minimizing heat generation and extending the lifespan of machinery. By creating a protective film between surfaces, lubricants ensure smoother operation and prevent corrosion and rust.

What are the different types of lubricants available?

Lubricants come in various forms, including oils, greases, and solid lubricants. Oils, such as mineral oil, synthetic oil, and vegetable oil, are commonly used in industries like automotive and aerospace. Greases, which consist of oil dispersed in a thickening agent, offer excellent adhesion and are ideal for applications where oil may drip or be inaccessible. Solid lubricants, like graphite and molybdenum disulfide, are preferred for high-temperature environments or where liquid lubricants are impractical.

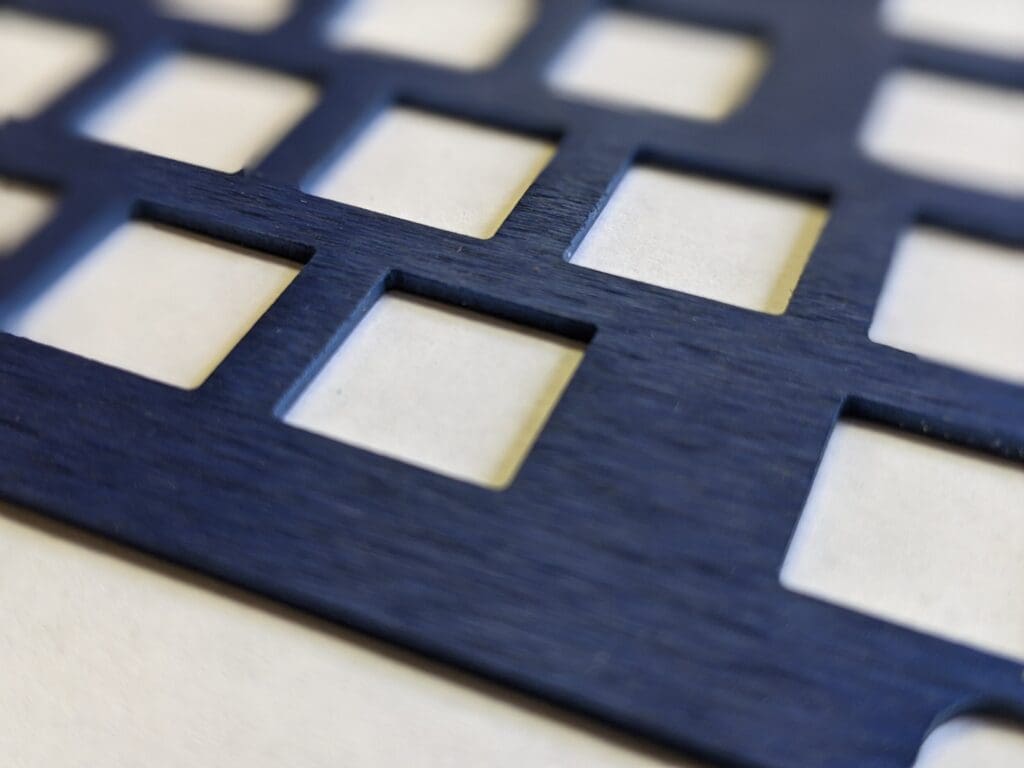

How do lubricants contribute to the performance of paved roads geocomposites?

Lubricants play a vital role in the production and installation of paved roads geocomposites, which are engineered materials used for road construction and rehabilitation. During manufacturing, lubricants aid in the blending of materials, ensuring uniformity and enhancing the flexibility and durability of the geocomposite. Additionally, lubricants facilitate the installation process by reducing friction between layers, enabling smoother placement and reducing the risk of damage or deformation.

What factors should be considered when selecting a lubricant?

When selecting a lubricant, several factors should be taken into account, including operating conditions, temperature range, load-bearing capacity, and compatibility with materials. It’s essential to choose a lubricant that meets the specific requirements of the application and provides adequate protection against wear, corrosion, and contamination. Additionally, environmental considerations, such as biodegradability and toxicity, may influence the selection process, particularly in industries with stringent regulations.

Lubricants are indispensable in various industries, offering benefits such as reduced friction, enhanced performance, and extended equipment lifespan. Whether in automotive engines, manufacturing machinery, or paved roads geocomposites, lubricants play a critical role in optimizing efficiency and minimizing wear and tear. By understanding the different types of lubricants available and their applications, businesses can make informed decisions to ensure smooth operations and maximize productivity.