Maximizing Efficiency and Precision with Cutting Tools in Geocomposite Sheet Drain Installation

In construction and civil engineering projects, the precise cutting of materials is crucial for ensuring accuracy, efficiency, and safety. When it comes to installing geocomposite sheet drains, cutting tools play a vital role in shaping and customizing materials to fit specific project requirements. This article explores the significance of cutting tools in geocomposite sheet drain installation, addressing common questions and providing insights into their usage.

Why are cutting tools essential in geocomposite sheet drain installation?

Cutting tools are essential for achieving precise measurements and shapes required to fit geocomposite sheet drains into various project configurations. These tools ensure that the drains seamlessly integrate with existing structures, preventing water accumulation and potential damage.

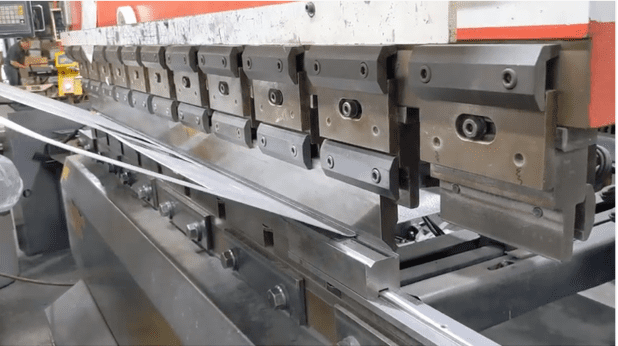

What types of cutting tools are commonly used in geocomposite sheet drain installation?

Common cutting tools include utility knives, circular saws, and specialized cutting machines equipped with sharp blades suitable for cutting through geocomposite materials. Utility knives offer versatility and precision for intricate cuts, while circular saws provide efficiency for large-scale installations.

How can cutting tools improve efficiency and productivity during geocomposite sheet drain installation?

By utilizing cutting tools, construction teams can streamline the installation process, reducing time and labor costs. Precisely cut geocomposite sheet drains facilitate faster assembly and minimize material wastage, resulting in enhanced productivity and project timelines.

What safety precautions should be observed when using cutting tools for geocomposite sheet drain installation?

Prioritize safety by wearing appropriate personal protective equipment (PPE), including gloves and safety goggles, to prevent injuries from sharp edges and debris. Ensure proper training and supervision for operating cutting tools, and always follow manufacturer guidelines and best practices to minimize risks.

In geocomposite sheet drain installation, cutting tools are indispensable for achieving precise cuts and shapes tailored to project specifications. From utility knives to circular saws, these tools enhance efficiency, productivity, and safety on construction sites. By harnessing the capabilities of cutting tools, construction teams can optimize their workflows and deliver high-quality results in geocomposite sheet drain installations.