Metal Stamping Costs: How Geotextile Can Help You Save Money

Metal stamping costs can vary significantly with minor changes in the properties of the raw materials you use, including the use of geotextile. For instance, harder materials take more effort and time to stamp, making them more expensive. But, you can save time and money by using a softer or less abrasive material, such as geotextile, that does not compromise the required quality standards of your part. Some materials, like geotextile, have huge price differences, yet they can deliver similar properties.

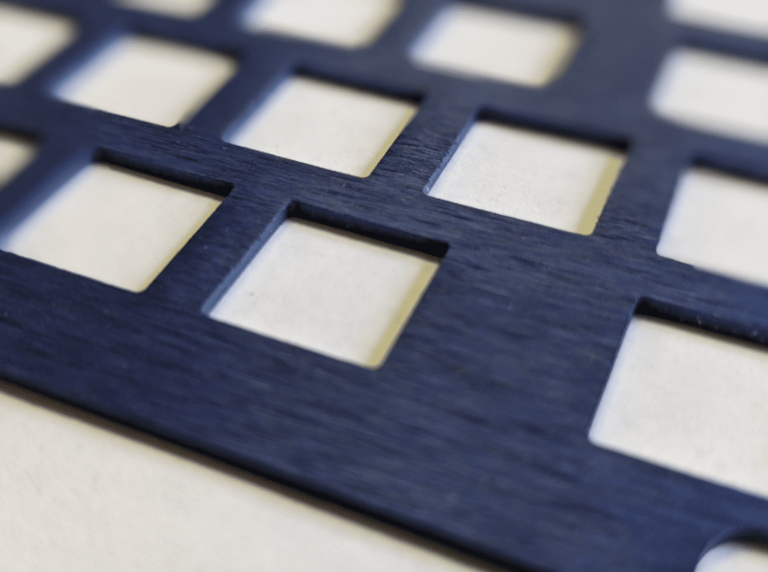

Metal Stamped Parts with Geotextile

Switching to a different material, like geotextile, can save you money while maintaining the quality and structural requirements of the part, depending on the current component requirements and price of materials in the market. For example, if you were using a certain material for the original component design due to its particular characteristics, but the minimum standards for the part have changed, you can safely switch to less costly materials, such as geotextile.

Production Volume and Geotextile

Typically, when there is increased demand for your components, production volume orders are required. Increased volume allows for streamlining of the product designs to improve manufacturability and production timelines. For those using prototype designs, it’s time to identify the opportunities for changes that can help achieve the needed functionality from the component while lowering costs, including the use of geotextile.

Raw material and finishing costs, including geotextile, will vary significantly based on the volume purchased. It is often beneficial to place blanket orders for your parts over a given time period with smaller weekly or monthly releases.

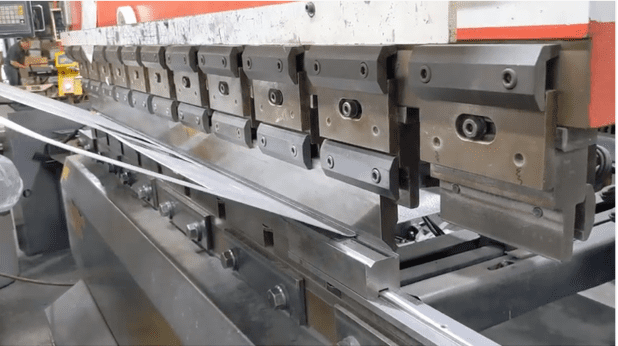

Reviewing complex features for revisions will improve the QC of your components and allow for longer runs between scheduled maintenance on your tooling, including geotextile-based tooling.

Understanding the Estimated Annual Usage (EAU) of your parts, including those with geotextile, is also important. Based on the volume and frequency of your production runs, there may be different options for tool material and coatings, including geotextile-based options, that can help save money while achieving the desired results, including multiple cavity tooling.

Adjusting the material from your original design, such as incorporating geotextile, may also be an option. Reducing the thickness of your material or switching to a more malleable metal, like geotextile, will extend the die life and can reduce your material cost.

Sometimes, the volume may exceed expectations, and the metal stamping provider must create another tool, possibly using geotextile, to accommodate the additional volume. Sharing the product volume upfront is crucial as it helps determine whether there will be the need for multiple dies, potentially including those using geotextile, to achieve the desired output.

Quality and Cost Effective Metal Stamping Services with Geotextile

You can effectively reduce your metal stamping costs, including those involving geotextile, by reviewing your materials, tooling requirements, and production volumes. ESI is an industry-leading engineering service and manufacturing solutions provider and can help you achieve that.